Engineered hardwood typically ranges from 3/8″ to 3/4″ in thickness. It strikes the perfect balance between durability and versatility.

Engineered hardwood flooring has gained popularity due to its structural stability and ease of installation. Its composition includes several layers, with a top layer of hardwood veneer and layers of plywood or high-density fiberboard beneath.

Unlike traditional hardwood, engineered flooring can withstand moisture better, making it an ideal choice for various climates and below-grade installations.

Its varied thickness options cater to different preferences and subfloor requirements, allowing homeowners to choose the best fit for their project.

With a substantial top layer, some engineered hardwoods can even be refinished once or twice, extending their lifespan and appeal.

Selecting the right thickness ensures a durable and aesthetically pleasing flooring solution that complements any home’s design.

Introduction To Engineered Hardwood

Engineered hardwood brings the beauty and warmth of solid wood to your home. This innovative flooring combines a wear-resistant hardwood veneer with a strong, plywood-like base.

Engineered hardwood stands up to moisture better than solid wood. Many styles and finishes are available to fit various decors.

Redefining Wood Flooring

Traditional solid hardwood floors are timeless, yet engineered hardwood offers a modern twist. The layers in engineered flooring make it stable and versatile.

Climate fluctuations have less effect on engineered floors. This quality makes them suitable for most home environments.

Components And Construction

- Top Layer: A thick enough layer of real wood for a genuine look.

- Core Layers: Multiple plywood layers create a sturdy base.

- Backing Layer: A final layer ensures balance and prevents warping.

Each layer is carefully pressed and bonded. This process provides excellent floor longevity. Engineered hardwood typically ranges from 3/8″ to 3/4″ thickness. This variety fits different needs and installation areas.

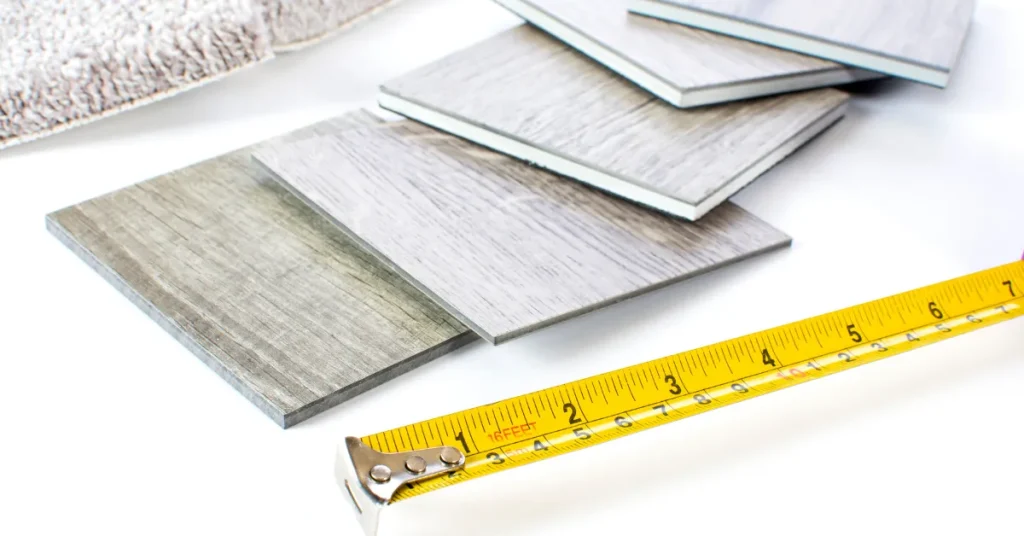

Measuring Thickness In Engineered Flooring

When choosing the right engineered hardwood flooring, thickness plays a big part. Measuring this aspect is vital before making a decision. Here’s how:

From Top To Bottom: Understanding Layers

Engineered hardwood flooring consists of multiple layers. At the top is the veneer, a thin layer of real wood that gives the flooring its beautiful look.

Below, layered plywood or high-density fiberboard adds stability. Knowing these layers is key to understanding overall thickness.

Average Thickness Ranges

Engineered hardwood floors come in various thicknesse ranging from 3/8″ to 3/4″.

| Veneer Thickness | Total Thickness in Inches | Total Thickness in Millimeters |

| 2 mm | 3/8″ | 9.5 mm |

| 3 mm | 1/2″ | 12.7 mm |

| 4 mm | 5/8″ | 15.9 mm |

| 6 mm | 3/4″ | 19 mm |

The veneer can vary typically between 2 mm and 6 mm. Thicker veneers can be sanded and refinished, extending the life of the floor.

Remember, total thickness affects durability and feel underfoot. Understanding these specs is essential for a smart purchase.

Importance Of Plank Thickness

The thickness of engineered hardwood plays a crucial role in its performance. This aspect influences not only the board’s durability and lifespan but also its insulation and sound-dampening properties.

Understanding plank thickness helps in making an informed decision suitable for various spaces.

Durability And Lifetime

Thicker planks of engineered hardwood mean enhanced stability. This results in a floor that withstands daily wear and tear better over time. A thicker hardwood layer allows for refinishing and sanding, potentially extending the lifetime of your floor.

- Enhanced wear layer: Offers multiple sanding cycles.

- Greater stability: Reduces the likelihood of warping or bowing.

- Quality investment: Thicker planks can increase home value.

Impact On Insulation And Acoustics

Engineered hardwood thickness also affects thermal and sound insulation. Thicker floors tend to retain heat better, contributing to a warmer room during cooler months.

Additionally, they improve room acoustics by absorbing sound, making spaces quieter.

- Better thermal retention: Keeps floors warm, slashes energy costs.

- Reduced noise levels: Thick planks dampen sounds, ensure peace.

- Enhanced comfort: Adds to the overall comfort of living spaces.

| Plank Thickness | Durability | Insulation | Acoustics |

| Thin Planks | Less durable, Limited sanding | Minimal insulation | Lower sound absorption |

| Thick Planks | More durable, Multiple sanding options | Improved insulation | Higher sound absorption |

Comparing Engineered Hardwood To Solid Hardwood

When homeowners eye elegance and durability for their floors, hardwood often tops the list. But the debate between engineered and solid hardwood can be puzzling.

Engineered hardwood presents a versatile alternative to solid hardwood. This modern variant comprises multiple layers.

On the surface, it mirrors solid hardwood’s appeal, with a thick veneer of real wood. Yet, it differs in build and resilience to environmental changes.

Let’s delve into the specifics, focusing particularly on the thickness aspect of engineered hardwood.

Thickness Variations

Engineered hardwood’s layered construction impacts its total thickness. The planks typically range from 3/8” to 1/2″ thick.

On the other hand, solid hardwood planks are usually 3/4″ thick. While both types can be sanded down, the thicker veneer of solid wood allows for more refinishes.

Engineered hardwood, however, offers another advantage. With its varied thickness options, it works well in rooms with varying floor heights. This variety promotes a seamless transition, a detail many homeowners appreciate.

- Engineered Hardwood: 3/8” to 1/2″ typically

- Solid Hardwood: 3/4″ standard thickness

Pro Tips For Selecting The Right Flooring

Choosing the right flooring depends on several factors. Here are some pro tips to point you in the right direction:

| Factor | Engineered Hardwood | Solid Hardwood |

| Moisture Resistance | Better suited for moisture-prone areas | Best for dry areas |

| Installation | More flexible installation options | Generally nailed or stapled |

| Longevity | Can last decades with proper care | Can last a century, may be refinished multiple times |

| Eco-friendliness | Uses less wood overall, more sustainable | Uses more solid wood |

Keep the room’s moisture levels in mind. Engineered hardwood excels in handling humidity. Consider the desired longevity.

Solid hardwood floors can last a lifetime with proper care. Acknowledge the installation process. Engineered hardwood is friendlier for DIY projects.

Think about the environmental impact. Engineered hardwood generally uses less solid wood, a nod towards sustainability. Balance these factors to navigate towards the flooring that will best suit your home and lifestyle.

Installation And Thickness

Understanding the installation and thickness of engineered hardwood floors is vital.

Thickness plays a key role in durability and feel underfoot.

It also affects how the floor handles temperature and humidity changes.

Subfloor Requirements

A proper subfloor ensures a successful installation.

Subfloors must be:

- Clean: Free of debris and dust.

- Level: Even surface without dips or hills.

- Stable: No movement or squeaking.

- Subfloors come in different types:

- Plywood

- Concrete

- OSB (Oriented Strand Board)

- Different thickness may require specific subfloors.

Adapting To Different Environments

Engineered hardwood fits various climates.

It can handle:

- Moisture: Resists warping and swelling.

- Heat: Tolerates warm conditions.

- Cold: Does not crack in cool temperatures.

- Its layers adapt to seasonal changes.

Thickness ranges typically from 3/8″ to 3/4″.

Thicker boards offer:

- More stability

- Longer lifespan

- Refinishing options

- Subfloors come in different types:

Maintaining Your Engineered Hardwood

Engineered hardwood flooring combines the beauty of traditional hardwood with increased durability. As a homeowner, understanding how to preserve its elegance is key.

Simple measures help maintain its high-quality appearance. Let’s explore cleaning and managing wear for this flooring type.

Cleaning And Upkeep

Regular cleaning keeps your engineered hardwood looking fresh. Here’s a quick guide:

- Sweep daily to remove loose dirt and particles.

- Use a microfiber mop for effective dust collection.

- Avoid water pools. Wipe spills immediately with a dry cloth.

- Employ suitable hardwood cleaners. Harsh chemicals can damage floors.

- Set a routine for deep cleaning every month.

Managing Wear And Tear

To protect your floors from damage, take these steps:

- Place protective pads under furniture.

- Use entryway mats to catch outside dirt.

- Avoid stilettos and sharp objects that may scratch the surface.

- Keep pets’ nails trimmed.

- Consider area rugs in high-traffic zones.

Mindful practices prolong your floor’s life and keep it shining.

FAQs About How Thick Is Engineered Hardwood

Is 3 8 Engineered Hardwood Too Thin?

3/8 inch engineered hardwood is not necessarily too thin; it can work well, especially for installations over existing floors or concrete. It’s durability depends on the quality of the top layer and the installation method used.

What Is The Total Thickness Of Engineered Wood Flooring?

The total thickness of engineered wood flooring typically ranges from 3/8 inches to 3/4 inches.

Is Engineered Hardwood Thinner Than Hardwood?

Engineered hardwood typically features a thinner top wood layer compared to traditional hardwood, which is solid throughout.

What Thickness Of Engineered Hardwood Is Best?

The ideal thickness for engineered hardwood flooring is typically between 3/8″ to 3/4″. Thicker options offer greater durability and can be refinished more times.

Conclusion

To sum up, engineered hardwood offers a balance of durability and aesthetics with varying thicknesses tailored to your project needs. Typically ranging from 3/8″ to 1/2″, this versatile flooring can enhance any interior.

Remember, selecting the right thickness ensures longevity and satisfaction with your engineered hardwood investment.

Choose wisely for a stunning, long-lasting surface underfoot.

Resources:

1. https://www.armysbir.army.mil/topics/engineered-domestic-hardwood-endangered-species/