MDF (Medium Density Fiberboard) typically weighs between 600-800 kg/m³. The exact weight can vary based on the thickness and brand.

Medium Density Fiberboard, widely recognized as MDF, is a popular choice in the construction and furniture industries due to its affordability and versatility.

Its weight is a key consideration for those working with this material, affecting everything from transportation costs to the physical demands of handling it.

Despite the variation depending on thickness, MDF is consistently denser than particle board yet lighter than natural wood, a middle ground that often proves advantageous.

Understanding its weight is crucial for professionals aiming to optimize structural integrity and design aesthetics. Those planning projects that involve MDF must factor in its weight for efficient project execution and safety protocols.

Basics Of Mdf

Exploring MDF, or Medium Density Fiberboard, unveils a versatile building material paramount in the woodworking and construction sectors. Its unique properties make it a popular choice for various applications.

Now, let’s dive into the basics of MDF and discover its composition, production methods, and common industrial uses.

Composition And Production

MDF comes from wood fibers blended with resins. The combination undergoes high pressure and temperature, resulting in a sturdy panel.

- Raw Materials: Wood waste products serve as the primary input.

- Binding Agents: Synthetic resins like urea-formaldehyde ensure fiber bonding.

Through pressing and heating, these components form dense, flat sheets. The outcome is a uniform, smooth product that craftsmen and builders value.

| Factor | Impact on Weight |

|---|---|

| Thickness | Thicker sheets weigh more. |

| Density | Higher density increases weight. |

| Size | Larger boards have greater weight. |

Common Uses In Industry

MDF’s versatility shines in numerous industrial applications:

- Furniture manufacturing for flat-packed items and cabinetry

- Interior decoration, in baseboards and window trims

- Architectural models, popular for its easy-to-cut nature

- Door parts, thanks to its durability

This material’s consistent structure supports a wide array of finishes, such as laminates, veneers, or paint. MDF satisfies both aesthetic and functional demands in industry. Its importance in crafting durable, attractive, and cost-effective products is unmatched.

Measuring Mdf Weight

Welcome to the world of woodworking and DIY projects, where the weight of your material matters just as much as its finish and durability.

Measuring MDF weight is crucial before starting any build. It will ensure you can handle and support your project effectively. Discover the weights involved and why they vary.

Factors Influencing Weight

Several elements affect how much Medium Density Fiberboard (MDF) weighs:

- Density: MDF comes in various densities, impacting weight.

- Moisture Content: The weight increases with higher moisture levels.

- Size: Larger boards naturally weigh more than smaller ones.

- Additives: Added chemicals can alter the original weight.

Standard Thickness And Weight Metrics

Here’s a glance at standard MDF board sizes and their typical weights:

| Thickness (mm) | Weight (kg/m2) |

|---|---|

| 6 | 4.50 – 5.50 |

| 12 | 9.00 – 11.00 |

| 18 | 13.50 – 16.50 |

| 25 | 19.00 – 23.00 |

These weights are estimates. Always check the manufacturer’s specifications for exact numbers.

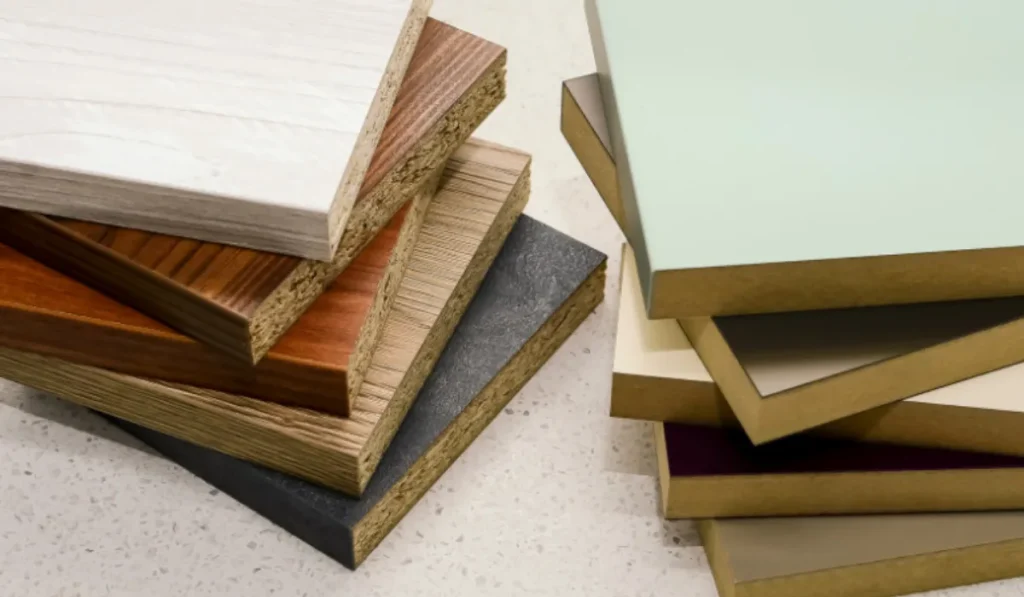

Comparison With Other Wood Materials

When considering wood materials for construction or crafting, weight plays a significant role. MDF, known for its consistency and affordability, is often compared to other wood products like plywood and solid wood.

Let’s dive into the specifics of how MDF stands up against these two well-known wood materials.

Mdf Vs Plywood

MDF (Medium Density Fiberboard) and plywood both serve as popular wood material choices. Yet, their weight can influence decisions for various projects. Typically, MDF is:

- Heavier per given thickness

- Smoother for ease of painting

- Less resistant to moisture

On the other hand, plywood boasts:

- Layers that offer strength

- Lighter weight for ease of handling

- Better resistance to warping

Weight per standard 4′ x 8′ sheet can drastically differ, with MDF often weighing more than plywood of the same thickness.

Mdf Vs Solid Wood

When MDF goes toe-to-toe with solid wood, the battle of weight gets interesting. MDF:

- Consistent weight due to engineered makeup

- Heavier than many types of solid wood

- Ideal for uniform projects

Solid wood:

- Varies in weight by species

- Typically lighter than MDF

- Favored for its natural beauty

For instance, a common size of MDF, such as a 3/4″ thick sheet, weighs around 100 pounds (45 kg), whereas solid woods like pine might weigh substantially less for a similar volume.

Considering the above, the choice between MDF, plywood, or solid wood will often depend on the specific needs of the project and the desired outcome.

Implications Of Mdf Weight

Medium-density fiberboard, MDF, is a versatile building material, loved by carpenters and DIY enthusiasts alike. The weight of MDF is an essential factor to consider. It will affect how you transport and use it.

Transportation And Handling Concerns

Moving MDF can be a challenge. It’s notoriously heavy. A standard 4×8 sheet can weigh anywhere from 50 to 100 pounds. The thickness adds to the weight.

- Driving safety: Heavy loads need secure fastening during transport.

- Moving equipment: Use carts and dollies to move large sheets of MDF.

- Team lifting: Avoid injury by lifting together for heavier sheets.

Structural Considerations In Construction

Builders need to think about MDF’s weight during design. The weight impacts the structural integrity of a project.

| MDF Thickness | Average Weight |

|---|---|

| 1/2 inch | 41 pounds |

| 3/4 inch | 61 pounds |

When using MDF:

- Check the load-bearing capacity of walls and floors.

- Use additional support for heavy MDF in shelving or cabinetry.

- Consider weight when planning to hang MDF elements.

Optimizing For Weight

Understanding how much MDF weighs is crucial when planning for transport, installation, and support. In projects that require material efficiency, weight optimization becomes a key factor. This section delves into selecting the best thickness of MDF for your needs and explores lightweight alternatives.

Choosing The Right Thickness

MDF comes in various thicknesses, each with its own weight and applications. Here’s a quick guide:

| Thickness | Weight per Square Foot |

|---|---|

| 1/4″ (6mm) | approx. 1.5 lbs |

| 1/2″ (12mm) | approx. 3 lbs |

| 3/4″ (19mm) | approx. 4.5 lbs |

Select thinner MDF for lighter projects, and thicker for durability and support.

Lightweight Alternatives And Innovations

For weight-sensitive applications, consider these lightweight solutions:

- Honeycomb MDF: A core with a honeycomb structure reduces weight while maintaining strength.

- 3D MDF panels: These consist of a thin layer of MDF contoured to be light yet robust.

- Ultralight MDF: A special blend of fibers creates a board that is up to 30% lighter than standard MDF.

These innovations ensure your projects are light, practical, and easy to handle.

FAQs About the Weigh of MDF

What Is The Weight Of A Standard Mdf Sheet?

MDF sheets come in various sizes, but a standard 4×8 foot sheet of 3/4-inch MDF typically weighs around 100 pounds. Size and thickness affect weight.

How Does Mdf Thickness Impact Its Weight?

Thicker MDF weighs more due to increased material density. For instance, 1/2-inch MDF is lighter than 3/4-inch. Weight scales up with material volume.

Is Mdf Heavier Than Plywood?

Yes, typically MDF is heavier than plywood of the same thickness. MDF’s density is higher due to its fine wood fibers and glue content.

Can Mdf Weight Affect Shipping Costs?

Absolutely. MDF’s weight impacts shipping costs significantly. Heavier loads may require more fuel and labor, increasing transportation expenses.

Conclusion

Understanding the weight of MDF is crucial for both logistics and structural planning. This guide has illuminated the factors affecting its mass, like thickness and size. Remember, specific weights vary between products and manufacturers. For precision, always check the data sheet of the MDF in question before commencing your project.