A 29 gauge metal roofing typically measures 0.0142 inches thick. This thinness makes it one of the lighter options for metal roofing materials.

Exploring the world of metal roofing reveals a range of options, each with their unique benefits and specifications.

Among these, 29 gauge metal roofing stands out for its balance of lightweight design and durability, offering a practical choice for both residential and commercial structures.

Its thickness, or rather thinness, contributes to its ease of installation and cost-effectiveness, making it a go-to option for projects that require a reliable roofing solution without the heft of its thicker counterparts.

As homeowners and builders often grapple with material choices, understanding the characteristics of 29 gauge metal roofing is essential in making an informed decision that aligns with both structural demands and aesthetic preferences.

The combination of low material weight and sufficient protection against the elements provides a compelling argument for its widespread use in modern roofing.

The Basics Of Metal Roofing

Choosing the right material for a roof is critical. Among many options, metal stands out for its durability, efficiency, and style. Understanding metal roofing basics ensures a smart investment that endures the elements.

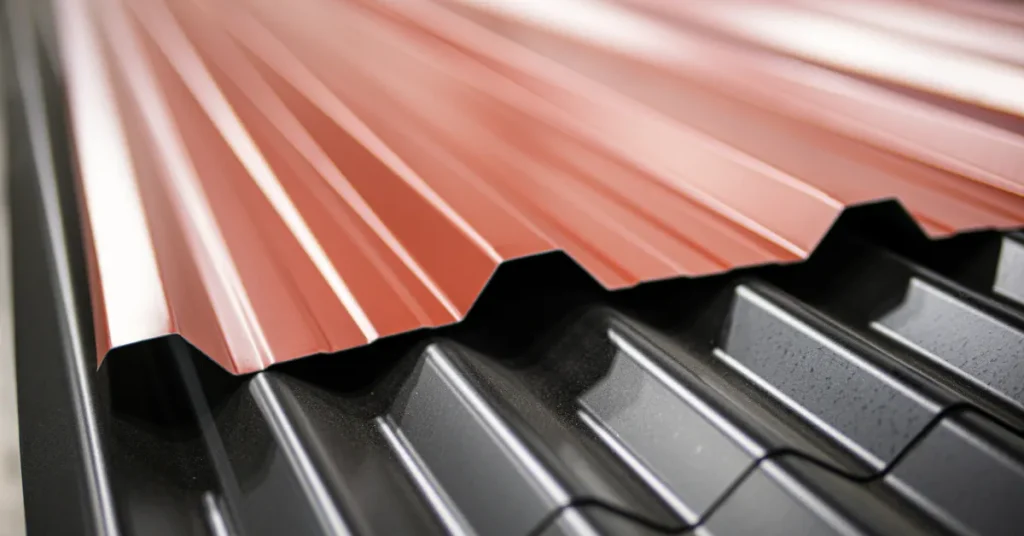

Material Diversity In Metal Roofing

Metal roofs come in various materials, each with unique benefits. These include:

- Steel: Popular for its strength and economical pricing.

- Aluminum: Known for its rust resistance and lightweight nature.

- Copper: Offers an elegant look with exceptional longevity.

- Zinc: Durable with a lower environmental impact.

Measuring Metal Thickness: The Gauge System

Metal roofing thickness is measured using the gauge system. The gauge number tells us how thick the metal is. Lower numbers mean thicker metal. Let’s look at 29 gauge metal roofing:

| Gauge Number | Thickness (Inches) |

| 29 Gauge | 0.014 – 0.0179 |

A 29 gauge metal roof is thin and often more economical. It suits areas with mild weather. For harsh climates, thicker gauges like 22 or 24 are better.

Decoding The ’29 Gauge’ Measurement

When choosing metal roofing, thickness matters. Understanding what ’29 gauge’ means is vital. It helps you pick the right material for your project.

How The Gauge Number Translates To Thickness

The word ‘gauge’ refers to the thickness of metal. In metal roofing, a higher gauge number means a thinner sheet. A 29 gauge metal roofing sheet is one of the common choices for residential buildings.

| Gauge Number | Thickness (Inches) |

| 29 Gauge | 0.0135″ |

| 26 Gauge | 0.0179″ |

| 24 Gauge | 0.0239″ |

| 22 Gauge | 0.0299″ |

Comparison With Other Metal Roofing Gauges

In comparison to others, 29 gauge metal is on the thinner end. Here’s how it stacks up:

- Thinner: 29 gauge is thinner than 26, 24, and 22 gauge.

- Lighter: It is lighter in weight, making it easier to handle and install.

- Economical: Being thinner, it’s also more cost-effective.

Remember, thicker gauges like 22 or 24 provide more durability. They withstand extreme weather better. Yet, for many climates and buildings, the 29 gauge offers a solid balance between cost, ease of installation, and performance.

Practical Implications Of 29 Gauge Thickness

Understanding the practical implications of 29 gauge thickness in metal roofing systems is key. This gauge represents the thickness of roofing sheets. It informs choices about durability, installation ease, and cost.

Durability And Longevity Considerations

Metal roofs are expected to withstand nature’s elements. The gauge number of metal plays a vital role in this. A 29 gauge metal thickness is commonly used in residential roofing.

It offers a balance between strength and flexibility. Thinner than 26 gauge but thicker than 30 gauge, it provides security against typical weather conditions.

- Resists physical damage from mild impacts

- Optimal for moderate climates; may dent under severe hail

- 29 gauge metal roofs can last up to 20-30 years with proper maintenance

Even though it’s lighter than thicker gauges, it still maintains essential protective qualities.

Impact Of Thickness On Roofing Performance

The thickness of your metal roofing impacts how well it will perform over time. While 29 gauge is thinner and more economical, it’s still effective for many homes.

It provides enough protection against the elements for a reasonable cost.

- Lightweight nature makes for easier handling and installation

- May lead to lower labor costs and quicker installation times

- Less structural stress on buildings, making it good for older homes

Wise consideration of the roofing environment ensures optimal performance.

Installation Factors For 29 Gauge Metal Roofing

Understanding the nuances of installing 29-gauge metal roofing is key to a successful project. This thin roofing material requires particular attention to detail. Delve into the intricacies of such an installation process.

Tools And Techniques For Handling Thin Metal

Working with 29-gauge metal demands precision. The right tools make a difference.

- Tin snips for cutting sheets.

- Seamers and folding tools to shape edges.

- Use a roofing nail gun with care.

- Maintain a metal brake for clean bends.

Treat the metal with respect to prevent warping. Techniques like avoiding over-tightening screws and measuring with precision help maintain integrity.

Pros And Cons Of Working With 29 Gauge Roofing

Consider the advantages and challenges of 29-gauge metal.

| Pros | Cons |

| Lightweight and easy to transport | More prone to denting |

| Easier to cut and install | Can be more easily damaged during installation |

| Cost-effective | Less impact resistance |

Handling the material correctly leverages the pros and mitigates the cons effectively.

Choosing The Right Gauge For Your Roof

When embarking on a new roofing project, selecting the right metal gauge is crucial for longevity and performance.

Understanding the thickness of materials like 29 gauge metal roofing helps inform a decision that balances durability, cost, and design. Explore key criteria to choose the best gauge for your roof.

Selection Criteria: Environment, Budget, And Aesthetics

The choice of metal roofing gauge should consider several factors:

- Environmental Conditions: Areas with harsh weather demand thicker gauges for increased resilience.

- Budget Constraints: While thicker gauges offer more durability, they can be more expensive. Balance cost with need.

- Aesthetic Preferences: Different gauges affect the look and feel of the roof. Choose one that complements your structure’s style.

Expert Recommendations And Industry Standards

Industry experts often suggest thicker gauges for areas prone to extreme weather.

- For high wind zones, a lower gauge number, indicating a thicker material, is preferable.

- 29 gauge metal roofing, while thinner, can be appropriate for mild climates and is more cost-effective.

Standards vary by region, but the International Building Code provides guidelines for minimum requirements.

Consulting with a professional ensures adherence to local codes and the selection of a proper gauge for your specific needs.

FAQs About How Thick Is 29 Gauge Metal Roofing

Is 29 Gauge Good For A Metal Roof?

Yes, 29 gauge is a common choice for metal roofing, providing a balance between durability and affordability for residential use.

Can You Walk On A 29 Gauge Metal Roof?

Yes, you can walk on a 29 gauge metal roof, but proceed with caution. Always wear soft-soled shoes and step on the purlins or supports, not directly on the panels. Follow manufacturer guidelines to prevent damage.

How Thick Is 29 Gauge Steel?

29 gauge steel is typically 0. 0135 inches or 0. 3429 millimeters thick. This measurement can slightly vary depending on the manufacturer and standards used.

How Far Can You Span 29 Gauge Metal Roofing?

The span for 29 gauge metal roofing typically ranges from 2 to 2. 5 feet between supports for optimal durability and performance. Always consult manufacturer guidelines for exact specifications.

Conclusion

Wrapping up our exploration of 29 gauge metal roofing, its thickness speaks volumes about its practicality.

Typically measuring 0. 36 millimeters, it’s a lightweight, durable choice for both residential and commercial projects.

Selecting this material promises a blend of longevity and cost-effectiveness, making it a smart investment for savvy builders and homeowners.

Resources:

1. https://www.tdi.texas.gov/wind/prod/rc/rc405.pdf